25 Years of LocoLabs: Bubbles, bananas, and beeswax - oh my!

BRAD HOFFERT, PRESIDENT AND CO-FOUNDERHere’s to 25 Years, LocoLabs!

Founded April 1, 1996

LocoLabs did NOT do any of this in the last 25 years:

- We didn’t put a man on the moon (but that’s been done).

- We didn’t watch the world get destroyed by nuclear weapons (but we get to worry about global warming).

- We didn’t create a cheap unlimited battery (but the world has created billions of expensive lithium batteries).

- We didn’t eliminate idiots and bullies (but they got Facebook and Twitter).

- We didn’t achieve unlimited knowledge (but the world got Wikipedia).

- We didn’t get rid of junk mail (but we got a bunch of new apps to communicate with so we can ignore our inboxes).

- We didn’t launch a Tesla into space playing David Bowie’s “Space Oddity” (but how can you hear it in the vacuum of space?)

- We didn’t develop a technological solution to all the world’s problems (but that is not from lack of trying).

So what HAS LocoLabs been up to for a quarter of a century?

Quite a bit! After 25 years of designing and building great products, LocoLabs shares a few highlights from working with – and for – some of the best and brightest people.

We could not have achieved this milestone without the dedication of past and present Loconians, our customers, suppliers and vendors. Thank you!

Here are some lessons learned from three of our favorite projects from the last quarter century. The best projects are those where you leverage your current knowledge and grow it, while solving new interesting problems. That is what a good engineer lives for.

Children’s Game Console:

Simple Fun Can Get Complicated – and Tasty!

When ex game developers have kids, something fun and interesting happens. They want to create the perfect game for their kids. That is the story behind BrightThings and the Bubble product. The great thing about this product was getting to think like a kid again. And to think about all the ways we could have destroyed this device when we were young, then designing around them.

Lessons Learned:

- Suppliers can be fickle. Plan ahead. One stopped building our plastics to build car bumpers instead; fast transition to an alternate supplier was critical.

- Interpreter writing skills can come in handy. To develop game cartridges, we had to develop a compact language to save on the cost of cartridges and CPU power.

- Keeping tabs on the production line is critical. Using a real-time data gathering database to look for anomalies, we were able to keep yields above 98%.

- Who says there is no accounting for taste? Children’s toys need to pass a certified lick test. To make sure no dangerous chemicals come off while licked or chewed. Yum!

DVD Rental Kiosk:

Things can go bananas!

When McDonalds got creative about repeat customers, they invested in self-serve DVD rental kiosks for their lobbies. That was the genesis of Redbox. Our job was to build a reliable, reproducible robotic kiosk that could manage over 500 DVDs.

Lessons Learned:

- Building dispensing Kiosks is pretty easy but building kiosks that can accept things from users is hard! You quickly learn about the sneaky and stupid things users can do to you. Building in robust logging and intelligence helped us keep the kiosks running, even when banana peels were returned instead of DVDs.

- Not all flex cables are created equal. A previous team’s prototype had intermittent operation; with a microscope we identified stress fractures in a flex cable that was improperly routed, resulting in a bend radius that exceeded the manufacturer’s spec.

- It’s good to be grounded. A previous prototype team had neglected to specify a ground plane in a PCB carrying critical signals as well as motor power, resulting in optical encoder signals getting scrambled once in a while, which caused the calibration to fail, jamming DVDs.

- Overspecification is expensive. The racks for the 500 DVDs were originally specified to be machined to tight tolerances. To reduce cost, we created software to auto-calibrate the racks to find the center. This allowed injection molded racks to be used and resulted in higher reliability.

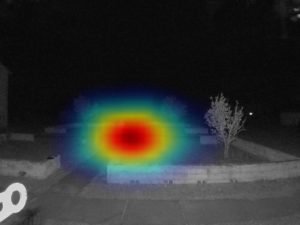

DTRA Gamma Imaging Spectrometer:

Fun, Challenging, Sticky, and Sensitive! Wait, are we talking about the US government?

When you are sending personnel into an unknown radiological situation, bad things can happen. DTRA knows a lot about that issue, especially in the area of identification of radiological threats. DTRA helped usher in a new technology to provide a real-time visual image of radiation contamination to identify sources, threat level, and to guide teams to avoid or contain them. We built numerous Cadmium Zinc Telluride CZT imaging systems to get these systems ready for deployment with the US army.

Lessons Learned:

- This was perhaps the most fun and challenging customer we have ever worked with. The DTRA team are brilliant, driven and hungry for new solutions to difficult problems.

- Bees Wax works brilliantly up to a certain temp. For high voltage signals, bees wax is an excellent material for insulating against arcing. (As long as you don’t get near its melting point. Then you’ve got a sticky situation!)

- MIL-SPEC batteries are great but expensive. There is a reason why batteries that can take a bullet are expensive. It’s easy to dismiss some requirements as over the top when it comes to building military gear, but it is all about understanding and managing requirements.

- EMP hardened gear is impressive. Learning how EMP pulses travel, and how their waveform can be used to signal equipment to shut down before damage can occur, was really cool.

- CZT is sensitive to everything! That makes it great for identifying the location of gamma rays, but you must keep it at a steady temp, keep it in the dark, crank it up to kilovolts, protect it from vibration, and throw out a ton of low yielding material.

Well, it’s been a wild ride so far and we look forward to where the next curve takes us!

Thanks again to all our wonderful vendors, customers, and of course the Loconians who have made it all happen.

About

About

Brad Hoffert

Brad is the co-founder and President of LocoLabs, where he oversees business development, sales, marketing, and strategy. He often lends his expertise on hardware, software, and mechanical design to help clients solve their toughest design challenges.

What makes Brad tic, in his own words:

“Solving difficult problems is what gets me out of bed in the morning. I started LocoLabs to fuel that desire. LocoLabs designs products in partnership with select customers who need a team of creative, innovative, curious geeks with a passion to create great products.

I excel at refining ideas into concepts, concepts into designs, and designs into production. I am passionate about customer communication and delivering awesome solutions. They can be Proof Of Concept (POC) or Minimum Viable Products (MVPs), or converting POCs or MVPs into volume production. Turning around troubled products, designs, or customer teams is a favorite challenge of mine.

I have found that the key to success in product design is pulling together the best team with the ideal mix of skills and a shared passion. I excel at building teams and providing direction and guidance to the process. 90% of work at many companies is done by 10% of the people. I seek out those 10% and put them together in a collaborative atmosphere and enable them with the best tools to achieve success.”

For 25 years, LocoLabs has specialized in the design and development of complex hardware and software products. Headquartered in the Silicon Valley in California, LocoLabs is a design and manufacturing partner that helps companies bring production-ready designs to market faster and more easily.